For almost any metals, fiber laser machines provide readable marks quickly and efficiently. They’re ideal for engraving all types of metal surfaces. Examples include aluminum, anodized aluminum, steel, stainless steel, magnesium, lead, and zinc.

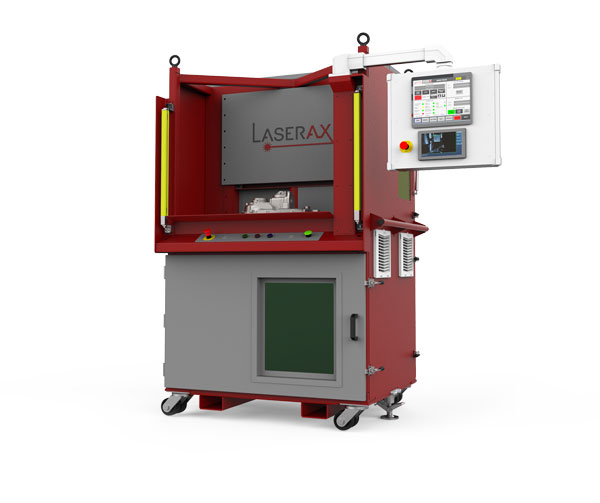

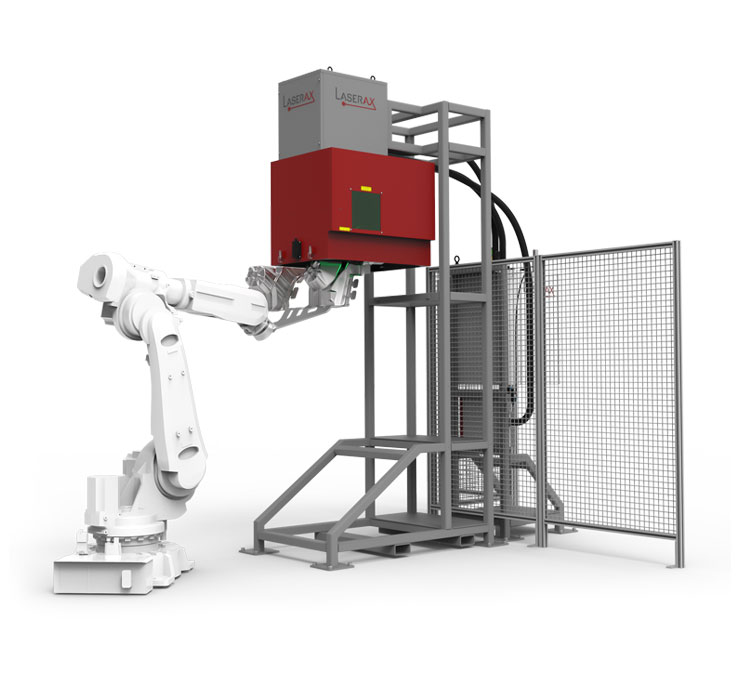

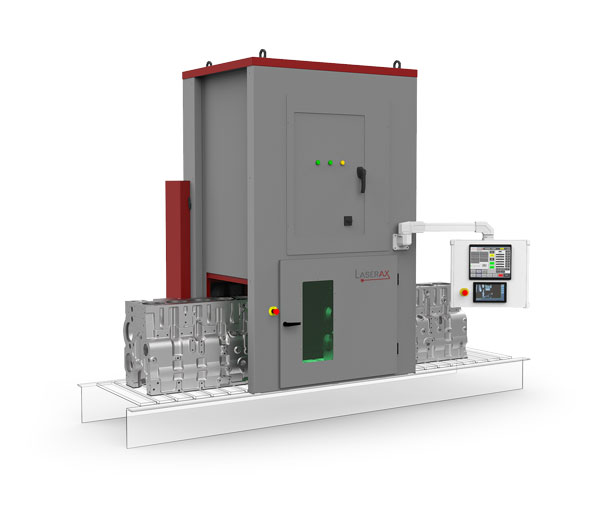

Fiber laser machines are low maintenance, use no consumables, and create high-contrast marks. You can use them to permanently mark data matrix codes, QR codes, serial numbers, barcodes, logos, and more.

Laser engraving metals with barcodes, serial numbers, and logos are very popular marking applications on both CO2 and fiber laser systems.

Thanks to their long operational life, lack of required maintenance and relatively low cost, fiber lasers are an ideal choice for industrial marking applications. These types of lasers produce a high-contrast, permanent mark that does not affect part integrity.

Laserbeschriftung Metall is useful for working with metals and is mostly used in the manufacturing and construction industry.

Main Processing Types

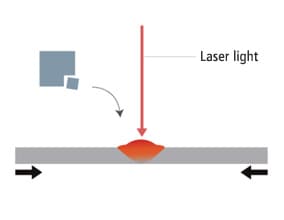

Cutting

Laser light irradiates a fixed point, usually with repetition to melt the material. The laser can easily melt through thin metals, fabrics, and leather. Because there is no contact, it does not cause a reaction with the item processed. Deformation and cracking is kept to a minimum. In addition, because it is possible to specify processing areas in extreme detail, it is possible to create localized holes or cuts in places where traditional cutting tools cannot fit.

Soldering

Laser irradiation is used to heat solder paste that then joins metals. This irradiation is highly localized allowing for extremely precise soldering compared to traditional methods. This precision also reduces the head effected zone on the parts.

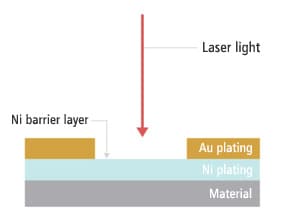

Solder Barrier

Electronics continue to get smaller and thinner. As a result, connector terminals need solder barriers (nickel barriers) to stop the soldering from expanding. Conventionally, masking was used on locations where electroplating was not necessary. However, removing the mask material took time and effort. Surface layer removal using laser light is effective in these cases.

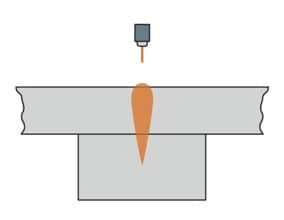

Welding

Laser welding irradiates two targets at the focal point and joins them together by melting and the soldifying the metal. It is possible to irradiate a pinpoint with high density energy and complete the process at high speeds. Material distortion due to heat is kept to a minimum. In the past, deformation occurred easily, but now even thin materials can be welded.

Suitable metals for laser marking and engraving:

- Stainless Steel

- Aluminum

- Anodized aluminum

- Hardened metals

- Alloyed steels

- High-speed steels

- Titanium, titanium alloys

- Carbides

- Brass

- Copper

- Precious metals (e.g. silver, gold)

- Coated metals